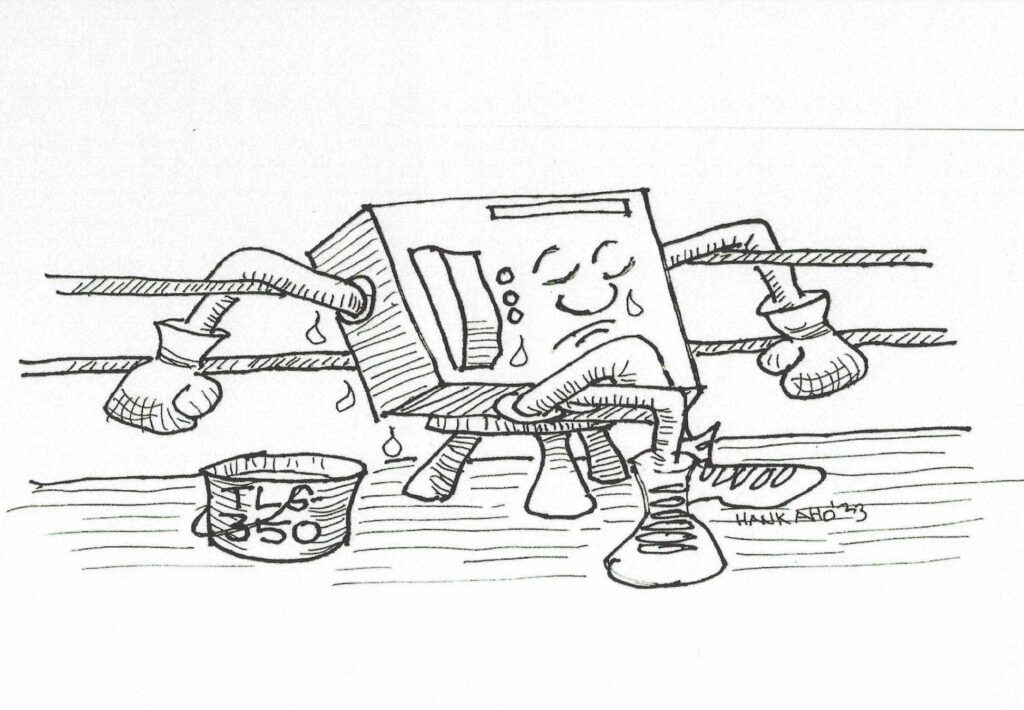

Requiem for a Heavyweight¹

Over a quarter century ago, I wrote an article for LUSTLine entitled “The ABCs of ATGs.” (Issue #24, July 1996.) In the article, I told the sad tale of a tank owner who kept running out of super unleaded gasoline prematurely but refused to believe that he had a massive leak in his tank. His automatic tank gauge (ATG) had twice determined that the tank was leaking, but an unhelpful tank technician had solved the problem by removing the offending probe from the tank. Operating on the theory that the fuel was being stolen, the tank owner spent several nights in his closed gas station waiting to catch the thief. He finally locked up the tank and the dispenser and monitored the fuel level with a gauge stick to determine that he was losing fuel. At this point, he had lost 10,000 gallons of fuel from a tank a half mile from the town’s water supply.

I expect such scenarios are a good deal less common these days as tank technicians and tank owners have a better understanding and greater confidence in their ATGs. Back then, ATGs were just coming into their own, evolving from being viewed as overly expensive gauge sticks to helpful tools in managing a storage system. In this article, I want to recognize the role that ATGs, especially the Veeder Root TLS 350, have played in bringing about the UST world we have today.

The Way We Were

The last 40 years have seen remarkable changes in fuel marketing[2]. The number of tanks has declined dramatically from upwards of 2 million down to half a million, while annual gasoline consumption has increased from 1.2 billion gallons in 1983 to 1.6 billion gallons in 2022. Obviously, this means that the volume of fuel sold from a typical fuel tank has increased substantially, from an average of 600,000 gallons per year per tank to 3.2 million gallons per year per tank.

As the petroleum marketing industry has evolved, tank gauges have evolved with it. Tank gauges started out nearly 50 years ago as a more convenient way to measure the fuel in an underground tank than a wooden stick. But in that era, accurate inventory recordkeeping was most often deemed too much of a bother and ‘taking inventory’ most often meant sticking a tank to see whether it might be time to order another load of fuel. It is easy to see why the market for a tank gauge that was hundreds of times more expensive than a wooden stick was a hard sell in those days.

Enter RCRA Subtitle I

The advent of Subtitle I of the Resource Conservation and Recovery Act (RCRA) in 1984 established a national regulatory program for USTs. The rules that followed in 1988 included requirements to reliably detect reasonably small leaks in tanks. This created a new possibility for ATGs: What if tank gauges could also be used for leak detection?

At the time, this was a fairly radical idea because the most common method for detecting small leaks was volumetric tank testing that required special equipment and trained technicians. Most tank tightness tests also required that the storage system be overfilled so that all components of the system (e.g., vent pipes, tank top fittings, and bungs) could be tested. Fire codes also set a standard of being able to detect a leak of 0.05 gallons per hour (gph). For in-tank measurement devices such as a tank gauge, overfilling was not possible and finding leaks of 0.05 gph was a daunting standard to meet.

But the authors of the federal rule saw value in leak detection methods that, although not up to the standards of a tightness test, could be applied routinely by the station operator with little interference with station operations. Plus, there would be no additional cost after the original expense of purchasing the equipment. In 1988, the federal regulations blessed the concept of only testing those portions of the storage system that routinely contained product. The rules also loosened the standard for leak detection to 0.2 gph in exchange for increased frequency of testing.

After the federal rules were published, tank gauge salespeople had another angle besides inventory to promote their product: ATGs that could meet the leak detection standard of the regulations could be sold as a regulatory compliance tool. ATGs provided the only method of leak detection described in the regulations that offered the business benefit of improving the ease and accuracy of inventory management, as well as providing regulatory compliance.

The TLS-250

At the time of rule publication, the state-of-the-art in ATGs was the Veeder Root Tank Level Sensing (TLS) 250. It could provide inventory information, print reports to document fuel deliveries, and had a 0.2 gph tank test function— but it could not do much else. The probe technology was based on electrical capacitance, which was reasonably good because it had no moving parts, but barely adequate for finding 0.2 gph leaks.

In 1990, another problem appeared for the TLS-250. The Clean Air Act that year mandated the large-scale use of oxygenated fuel (remember MtBE?)[3] in areas of the country with air pollution issues. Oxygenated fuel was initially required for wintertime use in 1992, and then year-round in 1995. The capacitance probe used by the TLS-250 would not work well in oxygenated fuel.

Enter the TLS-350

Around 1993, Veeder Root introduced the successor to the TLS-250, the TLS-350. The TLS 350 was designed to work with magnetostrictive probe technology[4], a much more accurate and reliable method of measuring the liquid level than capacitance probes. Additionally, magnetostrictive probes worked equally well in all motor fuels, oxygenated or not.

ATG features soon began to multiply. With the addition of a pressure sensor in the piping, the TLS-350 could perform piping leak detection, in addition to tank leak detection. Now, a single device could automatically meet all of a storage system’s monthly leak-detection requirements. The TLS-350 console also had the ability to monitor many types of leak detection sensors that could be located in double wall tanks, piping sumps, under dispenser containment, observation wells, or any other location that needed monitoring. In addition, the TLS-350 had remote communication capabilities. Initially, this was primarily via phone lines, but soon the TLS-350 could be connected to the internet.

For astute businesspeople, the benefits of the TLS-350 became very compelling:

- Leak detection for both tanks and piping could be done automatically and almost painlessly after the initial capital investment.

- Inventory accuracy could be dramatically improved.

- Fuel delivery logistics could be greatly facilitated because a fuel dispatcher could see from her desk exactly how much fuel was in a tank and schedule a delivery accordingly.

After December 23, 1993, the five-year phase-in schedule for leak detection that had been a key part of the 1988 federal regulations was complete. All active storage systems now required leak detection. While there were cheaper options for leak detection compliance, none offered the additional business benefits of an ATG.

The capabilities of the TLS-350 soon expanded to include continuous tank testing, so that a facility did not have to interrupt fuel pumping operations to conduct a tank leak test. The introduction of continuous leak detection meant that scheduling tank tests that might interfere with 24-hour fueling operations was no longer necessary.

ATG capabilities continued to expand. As remote communications became more sophisticated, remote alarm monitoring made it possible to outsource alarm response and associated service calls. Remote communications also made it possible to have recordkeeping services where compliance paperwork for all of a tank owner’s facilities could be easily stored in dedicated offsite databases. The store owner’s focus could be selling fuel and merchandise, while fuel alarms and regulatory compliance were automatically taken care of.

By the turn of the millennium, the TLS-350 had become the workhorse of the industry and the dominant brand of ATG in the U.S. But the Veeder Root engineers were still not done with the TLS-350.

Enter Blending Dispensers

As the volume of fuel sold per facility increased, retailers looked for ways to increase storage capacity that did not involve the expense and disruption of installing additional tanks. The sale of three grades of gasoline had been a longstanding tradition since the elimination of leaded gasoline in the 1980s. Even though sales volume of regular gasoline was many times the volume of middle and premium grades, most facilities had three tanks that were all the same size. This meant that for the mid-and premium-grades the available storage capacity was greatly underutilized. But the thought of selling only two grades by converting a mid- or premium-grade tank to regular-grade fuel was not attractive.

The answer came with the advent of accurate blending dispensers that made it possible to store only regular and premium gasoline, with the mid-grade product blended on demand in the dispenser. The elimination of the mid-grade tank oftentimes allowed a doubling of the storage capacity for regular fuel.

Traditionally, this change to fuel blending would have involved the installation of siphon piping connecting the two regular tanks to equalize the fuel level in each tank. This would have meant breaking concrete and excavating to the tank tops, with significant cost and disturbance.

Then, engineers realized that the tank gauge already could control the submersible pumps as part of the piping leak detection function, and the tank gauge knew the level of fuel in the tanks. With some software changes, it would be possible to have the ATG turn on the pump in the tank with the higher level of regular gas whenever a customer called for fuel. This would keep the tank levels in the two regular tanks more or less equal without the need for a physical piping connection between the tanks. All that would be needed was minimal modification to the piping at the base of the dispenser without the need to break concrete or have any excavation. The creation of this virtual siphon by the tank gauge greatly simplified the conversion of facilities to blending dispensers to maximize the use of existing storage capacity. Today, blending dispensers and virtual siphons are very common features at busy gas stations.

To Everything There is a Season

In an era where electronic devices are outdated after a few years, the TLS-350 has performed and continues to perform admirably after decades, but there are limits.

Connectivity

Today, connectivity is a key element of our society and businesses. We want the ability to access and control nearly everything from anywhere. Connectivity allows remote troubleshooting of equipment, remote updating of software, remote management of fuel delivery, remote compliance and recordkeeping, and management of many other aspects of a fuel facility.

But connectivity comes with security concerns. How do we keep prying eyes out of our data? How do we keep bad actors from holding us hostage? While there are techniques we can use today to secure information and devices, these issues hardly even existed when the TLS-350 was created. The TLS-350 has fundamental security vulnerabilities that cannot be addressed within the existing hardware.

Data Storage

Today’s data storage technologies are vastly superior to what was available when the TLS-350 was born. Back then, a megabyte of storage was a huge amount, while today we talk of storage in terms of a terabytes—equal to a million megabytes. While the TLS-350 can hold no more than the last 50 alarms in its history, today’s tank gauges can record thousands of alarms in memory, as well as multitudes of fuel deliveries and other events.

User Interface

The TLS-350 is outdated in other ways as well. A two-row, monochromatic, alphanumeric, 24-character display seems out of the Stone Age when compared to today’s colorful touch-screen graphical user interfaces.

Rest in Peace

So, as of December 31, 2021, the TLS-350 has come to the end of the production line. But with the sheer number of units out there, and the longevity they have displayed over the decades, it will likely be a while before the last operating TLS-350 is laid to rest.

The TLS-350 has played a central role in improving the management of UST systems. While regulatory requirements helped ATGs blossom, ATGs helped tank owners achieve the leak detection and tank management goals of the regulations. It has been a long and mutually beneficial relationship which shows every sign of continuing into the future.

A Salute

To the engineers who designed and refined the TLS-350, the technicians who installed and serviced them, the salespeople who promoted them, and the tank owners who invested in them: Thanks for a job well done!

Postscript

I know there are other ATG manufacturers with fine products. I do not mean to slight what other ATG brands have contributed to the evolution of fuel system management, only to honor the passing what we all must acknowledge is a heavyweight in the field.

Disclaimer

This article is meant to highlight the role that the Veeder Root TLS-350 has played in fuel management and underground storage system regulation over the last several decades. Explicit mention of the Veeder Root TLS-250 and TLS-350 in this article does NOT constitute endorsement of these devices (or any other tank gauge) by the author, NEIWPCC, or the U.S. EPA.

[1] Apologies to Rod Serling.

[2] For an overview of these changes, see, “When Winkle Woke Up,” LUSTLine #71, September 2012.

[3] See “MTBE – If Ye Seek It, Ye May Well Find It…And Then What?” in LUSTline Bulletin #24, July, 1996 for an overview of MTBE issues.

[4] See the “ABCs of ATGs” article in LUSTline Bulletin #26, July 1996, for a description of how this technology works.