High Resolution Site Characterization – Coming to a LUST Site Near You?

The LUST community has made tremendous strides in cleaning up releases from UST systems, with more than 500,000 cleanups completed and thousands more completed each year. Due to advances in science and cleanup technologies, we’ve increased our understanding and our ability to clean up LUST releases. However, we still have nearly 60,000 confirmed releases to address, and more than 4,000 new releases are reported each year. We regularly hear about innovative approaches and emerging technologies to address this backlog of LUST sites. With than in mind, I want to share some recent work EPA completed regarding high-resolution site characterization (HRSC).

There are many types of HRSC for use in a wide variety of contaminants and geologic settings. EPA describes HRSC as strategies and techniques that use scale-appropriate measurements and sample density to define contaminant distributions, and the physical context in which they reside, with greater certainty, supporting faster and more effective site cleanup. In other words, more data is better. We decided to study the applicability of HRSC to LUST sites, focusing on driven probe, direct sensing investigations, which have been the most widely used HRSC techniques used with UST releases.

EPA has been encouraging the use of HRSC at large, complex RCRA and Superfund sites to help focus site investigations and improve cleanups. HRSC techniques identify the contaminant mass in soil and groundwater, including Light Non-Aqueous Phase Liquid (LNAPL). HRSC provides a detailed geologic profile of soil zones that are storing and transmitting contaminants. In contrast, HRSC use at LUST sites has not been widespread. A few states are using HRSC at some of their UST release investigations, but most petroleum UST release sites continue to be assessed using traditional monitoring well investigation techniques. Our study examined the potential utility, benefits, and cost impacts of using HRSC at various types of LUST sites.

ITRC’s guides for LNAPL (LNAPL-3), petroleum vapor intrusion, advanced site characterization, and fractured

bedrock describe

high-resolution technologies and sampling approaches in detail.

EPA study of HRSC at LUST Sites

In 2022, EPA worked with its economics consultant, Industrial Economics, Inc., on a study called High Resolution Site Characterization (HRSC) at Petroleum Underground Storage Tank Release Sites – Applicability, Benefits, and Costs. The study goals were to:

1) Quantify the costs and benefits of HRSC investigations and their impacts on overall project costs and time at petroleum UST release sites,

2) Identify situations where HRSC is likely to provide a benefit in site characterization compared to the use of only traditional, non-HRSC methods at petroleum UST release sites, and

3) Identify barriers to more widespread use of HRSC.

The study results indicate that in comparison to traditional boring and monitoring well investigations at petroleum UST release sites, HRSC provides the following benefits:

- Provides a more complete understanding of the release site geology and contaminants.

- Increases confidence in corrective action decisions.

- Helps achieve No Further Action sooner.

- Often results in lower project costs by better targeting remedial activities.

HRSC can lower overall LUST site cleanup costs

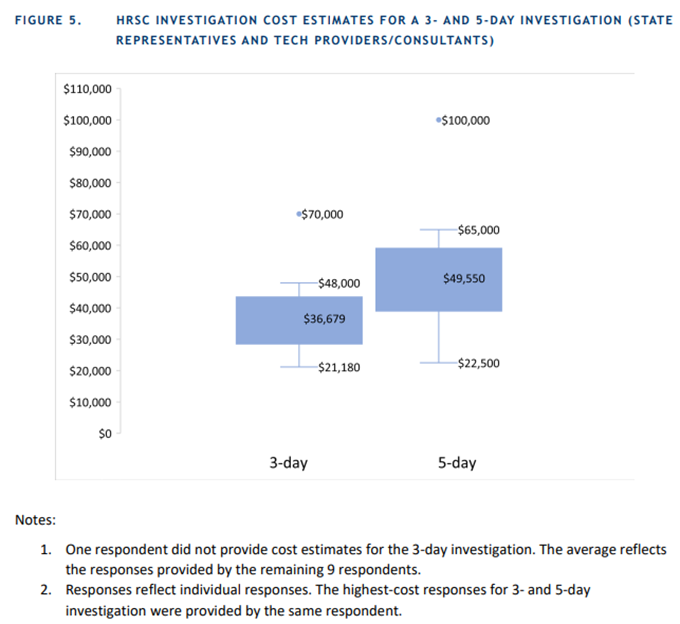

Experts interviewed as part of the EPA 2022 study concluded that average costs of HRSC investigations at typical petroleum UST release sites are $36,679 for a 3-day investigation, and $49,550 for a 5-day investigation.

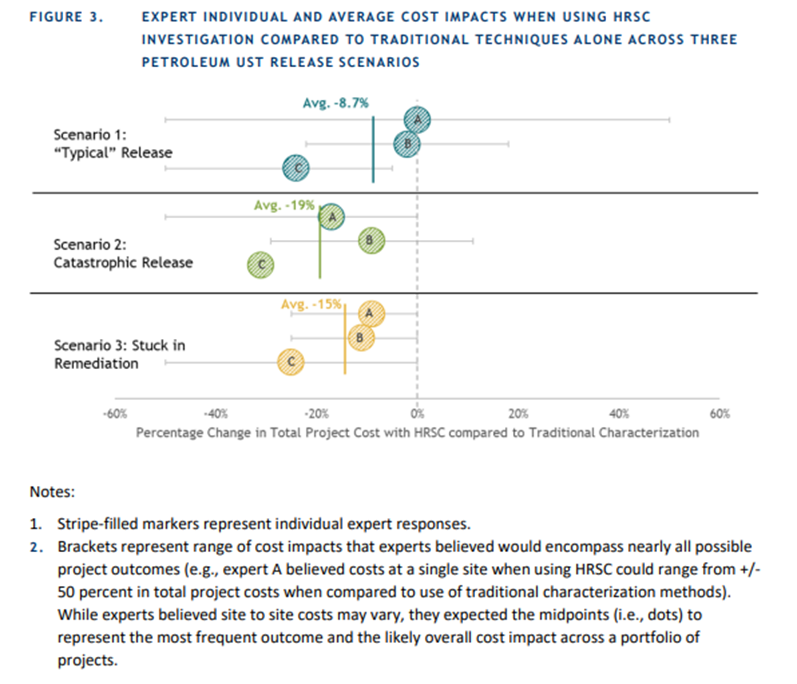

For three common petroleum UST release scenarios the expert panel concluded HRSC could save on average 9% to 19% in project costs — HRSC would sometimes add 20% to overall project costs on the typical UST release, and on other sites save 40%. On average HRSC would save 9% on overall project costs at typical UST releases. The experts concluded that HRSC would always save costs when investigating catastrophic releases and stalled remediation projects.

HRSC can reduce cleanup time at LUST sites

The experts in the study agreed that HRSC also saves time in the remedial process. Three experts analyzed three UST release scenarios, with and without HRSC and concluded that HRSC can save 3.3 years of a typical 10-year remediation project, 3.7 years off catastrophic release cleanups, which typically take 9 years to complete, and 8.5 years off 33-year timeframe for sites that are not progressing to their cleanup goals.

HRSC has widespread applicability at LUST sites

States, consultants, and practitioners identified many situations where HRSC was useful in developing the conceptual site model when collecting additional information was necessary. The study participants evaluated 15 different LUST site scenarios. All scenarios had at least one person support HRSC use and there was near unanimous support for using HRSC in 8 of the 15 scenarios.

HRSC Use Case Scenarios in EPA Study*

- When determining what level to place monitoring well screens and select screen lengths in sites with soil layers that have highly contrasting permeability.*

- Where a large release has occurred into complex layered soils and the pathways of travel are uncertain.*

- When contemplating an active remedy that will cost more than $100,000. Better targeting of the source area and understanding its relationship to the hydrogeology can save costs in an active remediation.*

- Where there are sensitive receptors nearby and the extent and potential movement of contaminants need to be determined with certainty and speed.*

- Where a large release has occurred, and it is important to identify the extent of LNAPL and the elevated dissolved phase plume, or its direction of movement, quickly.*

- Where LNAPL presence in monitoring wells or movement is not explained by the current CSM or is inconsistent with the groundwater gradient.*

- Before conducting a third round of monitoring well investigation to define the extent of the LNAPL source area of elevated dissolved phase plume.*

- Where one or more monitoring wells show persistent or recurring levels of contaminants of concern in excess of target cleanup goals.*

- When there is a need to differentiate between new and old releases.

- Where one or more monitoring wells show persistent or recurring levels of LNAPL that is not explained by the Conceptual Site Model (CSM).

- When contemplating a MNA or NSZD remedial strategy, but the CSM does not adequately quantify the volume of LNAPL or define the groundwater flow pathways.

- Where a remediation method has failed, and a new remedial approach is being contemplated.

- Where active remediation has been conducted for over 10 years.

- When chemicals, absorbents, or nutrients will be injected into the ground.

- When there is a need to present the CSM graphically to the public, stakeholders, or litigants, showing the relationship between groundwater elevations, the source area(s), soil layers, migration pathways, and the extant contaminated groundwater.

*Scenarios with near unanimous support for using HRSC.

Barriers to HRSC use at LUST sites

Despite potential benefits, barriers to HRSC use at LUST sites remain. In the study, experts identified a couple of technical barriers. There was widespread recognition that HRSC would not be used at sites where there were no significant data gaps – such as a “straightforward” UST closure where only limited contamination was identified and cleaned up during the excavation work. Also, uncooperative consolidated geology is a fundamental barrier to the use of direct sensing HRSC tools.

Beyond those two technical barriers, administrative and economic barriers remain that prevent wider HRSC use and application. LUST site practitioners and experts identified a number of barriers to wider use of HRSC to investigate UST releases, but there was little agreement on which barriers were most important. HRSC practitioners rated the lack of state fund reimbursement schedules for HRSC as a reason for not using HRSC, while state regulators pointed to the providers not proposing HRSC investigations as a significant barrier. Other barriers included the lack of guidance on when to use HRSC on petroleum UST release sites and on how to incorporate HRSC data into corrective action decisions. Some barriers seem to be “chicken or egg” situations. Overcoming these barriers to reap the many benefits of HRSC at LUST sites will require creativity and collective effort.

Conclusion

Data generated by the HRSC approach is often more detailed and comprehensive than traditional monitoring well investigations can yield, which allows for the creation of more complete conceptual site models (CSM), clearer communication with the stakeholders, more informed remediation decisions, quicker site closures, lower overall remediation costs, and ultimately, better protection of human health and the environment.

The results of our HRSC study can help inform site owners and other stakeholders on the best use cases for HRSC in site cleanups, including where it is most cost effective, and where it may inform selection of effective remediation techniques. This study points to an opportunity to improve environmental protection and to save time and money by expanding HRSC use at petroleum UST release sites. We’re going to work with our partners to spread the word about the benefits of HRSC at LUST sites. In addition, we plan to develop guidance for use of HRSC at federal-lead LUST cleanups in Indian Country.

Below you will find an article from our state partners in Michigan regarding use of HRSC at a LUST cleanup site. Have you also used HRSC in your state or at your LUST site? If so, I ask you to share your experiences with others. In particular, you may wish to contact EPA staff in your region, or Alex Wardle or Tom Schruben at our headquarters office.

Case Study from Michigan:

Alpena EZ Mart

2222 US Highway 23

Alpena, MI 49707

Facility #: 00018989

Confirmed Releases: REL-0004-16 and REL-0006-16

On January 7, 2016, a contractor identified red sulfur diesel beneath the sump of a dispenser. It was estimated that 5,000 gallons of red sulfur diesel was released as the result of a leak in the primary fuel line that then filled the secondary lines which then leaked at multiple locations from the tank dispensers. While conducting emergency response activities a second release was discovered on January 19, 2016.

Because of the volume of product released and a concern with potential for Non-Aqueous Phase Liquids (NAPL) to migrate beneath the building or off-site, excavation activities were conducted from January 7, 2016, through January 27, 2016. Soil was removed from around dispensers and canopy, creating a sump which allowed recovery of liquids through the use of vac trucks. In total, 40 temporary monitoring wells were installed to delineate mobile NAPL and to guide excavation activities, 2,386 tons of soil were excavated, and 42,504 gallons of liquids were removed.

A Laser Induced Fluorescence (LIF) investigation was conducted March 28, 2016, through March 30, 2016. Stock Drilling provided geoprobe services and the Ultra-Violet Optical Screening Tool (UVOST). The objective of the investigation was to collect information on depth, thickness, product type, and location of NAPL. 38 LIF borings were advanced with log standards supporting that the product released was diesel and that NAPL was generally located between 4.0’ and 6.0’ below ground surface (bgs).

Through the investigation, a previously unknown location of NAPL was identified and discovered to have migrated to the property boundary. Following delineation activities, additional material was excavated from this area and liquids were recovered by vac truck. Use of LIF at an approximate cost of $10,570.52 led to:

- Identification of a previously unknown impact.

- Successful mitigation of off-site migration.

- Acquisition of information that would later assist in the design and implementation of a remediation system.

Following the removal of source material and the mapping of the NAPL body, an air sparge/soil vapor (AS/SVE) extraction system was designed and mobilized to the site to reach cleanup objectives. The system was installed between March and June 2016. Utilizing information from the March LIF event, 41 sparge points were completed to a depth of 17.5’ to 18.5’ bgs and two SVE lines were installed. Equipment operated 12 hrs./day, seven days a week from June 6, 2016, through March 3, 2017.

A Closure Report was received by the Michigan Department of Environment, Great Lakes and Energy on February 26, 2019, and closure was granted on March 21, 2019. In total $590,384.64 in reimbursement was requested from the Michigan Underground Storage Tank Authority (MUSTA); after the $10,000.00 deductible, $580,384.64 in reimbursement was provided.

In Michigan we currently do not have any guidance or standard operating procedures for when high resolution site characterization (HRSC) should be performed. With it being recognized as a potentially valuable technology, the State Fund (MUSTA) provides reimbursement for this activity as long as it is considered a reasonable and necessary corrective action to secure restricted closure of the covered release and as long as our bidding requirements are followed. The Alpena EZ Mart Project is a good example of how HRSC used with existing practices can help direct cleanup activities, manage cleanup costs, and expedite the closure timeline.